Industry News

-

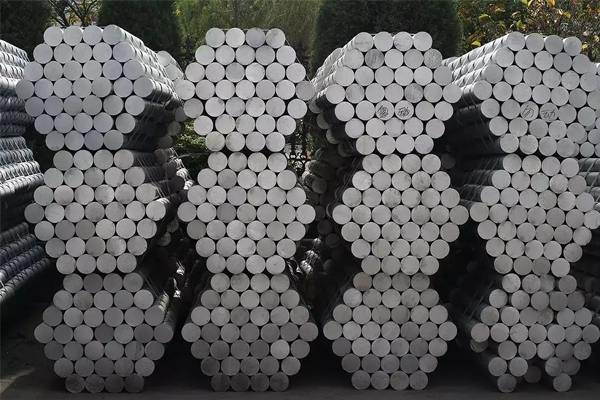

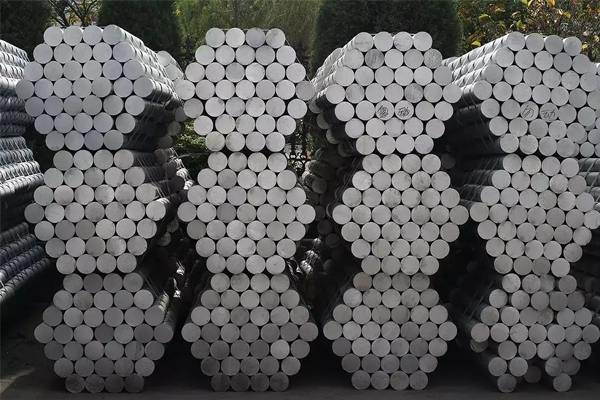

The material used in forging

The forging materials are mainly carbon steel and alloy steel, followed by aluminum, magnesium, copper, titanium and their alloys. The original state of the material is bar, ingot, metal powder and liquid metal. The ratio of the cross-sectional area of a metal before and after deformation is call...Read more -

The application of butt welding flange in petrochemical industry is described

Flange in oil and industry is still very common, we can see the use of butt welding flange in various categories of industry. However, the use of welding flange is the need to have a lot of attention, these attention is the need to pay attention to. So, what are the basic precautions for welding ...Read more -

The method of removing rust to improve the anti-rust performance of nonferrous metal forging parts

The rust removal methods to improve the anti-rust performance of non-ferrous metal forging parts are as follows: (1) Immerse the oil of forging parts into the mixture after treatment; (2) Pretreatment of forging parts; (3) preparation of treatment fluid; (4) Dip the pre-treated forging parts trea...Read more -

What problems will be encountered in the forging process

Forging processing process may encounter a variety of problems, specific we look at the detailed introduction of the staff. One, aluminum alloy oxide film: The oxide film of aluminum alloy is usually located on the die forged web, near the parting surface. The surface of the fracture has two char...Read more -

What are the inspection methods for large diameter flange quality?

The large-caliber flange is one of the flanges, which is widely used and implemented in the sewage treatment profession, and is well received and loved by users. So what are the inspection methods for the quality of large diameter flanges? The inspection method of large diameter flange quality is...Read more -

Non – standard flange forging process

The forging technology of non-standard flange includes free forging, die forging and tire film forging. During production, different forging methods are selected according to the size and quantity of forging parts. The tools and equipment used in free forging are simple, universal and low cost. C...Read more -

How to install stainless steel flanges in pipes

Stainless steel flange connection is an important connection mode in pipeline construction, mainly used for pipeline installation and connection, has a high application value. Stainless steel flange connection is to fix two pipes, pipe fittings or equipment respectively between two flange plates ...Read more -

316 stainless steel flange and 316L stainless steel flange performance and use differences

There are many grades of stainless steel in the classification, commonly used are 304, 310 or 316 and 316L, then the same is 316 stainless steel flange behind an L is what Thought? In fact, it is very simple. Both 316 and 316L are stainless steel flanges containing molybdenum, while the content o...Read more -

Flange local repair there are three methods

Flange application in many aspects, including petrochemical industry, energy industry, scientific research and military industry and other sectors of the national economy have played a very important role. However in the reactor in the refinery, flange production environment is very bad, need to ...Read more -

Installation sequence of butt welding flanges

Butt welding flange, also known as high neck flange, is a kind of pipe fitting, refers to the neck and a round pipe transition and pipe butt welding flange connection. Welding flange is not easy to deformation, good sealing, widely used, suitable for pressure or temperature fluctuation of pipelin...Read more -

How to prevent flange cracking

First of all, the cracking of stainless steel flange chemical composition analysis, analysis results indicate that the chemical composition of the stainless steel flange and welding data are in accordance with the relevant specifications. The brinell hardness of the flange neck surface and sealin...Read more -

What are the analysis methods of forging quality?

The main task of forgings quality inspection and quality analysis is to identify the quality of forgings, analyze the causes of forgings defects and preventive measures, analyze the causes of forgings defects, put forward effective prevention and improvement measures, which is an important way to...Read more