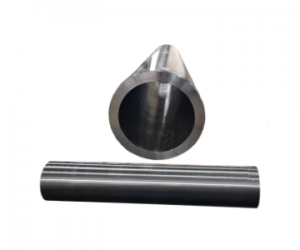

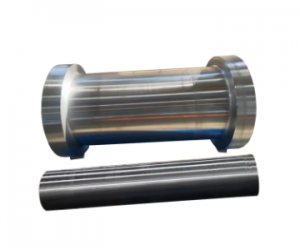

I-Tube inyanzelisa imingxunya

Iinkcukacha zemveliso:

Indawo yemvelaphi: shanxi

Igama lophawu: Dhdz

Isiqinisekiso: I-Asme, Jis, Din, i-GB, i-BS, e-en, i-ASTM, i-ASTM A370, API 6B, API 6b

Ingxelo yovavanyo: MTC, HT, UT, UT, Ingxelo yeNgxelo, uvavanyo olubonakalayo, En1043.1

Ukucaciswa: I-TUV / PED 2014/68 / EU

Ubuncinci be-oda ubungakanani: iqhekeza eli-1

Iphakheji yoThutho: Ityala lePlywood

Unyango lomhlaba: ipolishing

Ixabiso: Ukuxoxwa

Umthamo wemveliso: 20000 Ton / unyaka

| Izinto zezinto ezibonakalayo | C | Mn | P | S | SI | Cr | NI | Mo | Cu | N |

| I-A182 F51 | ≤ I-0.030 | 2.0 | ≤ I-0.030 | ≤ I-0.020 | <0.80 | 21-23 | 4.5-6.5 | 2.50-3.50 | / | I-0.20-0.24 |

| I-A182 F53 | ≤ I-0.030 | ≤ 1.20 | ≤.035 | <0.020 | <0.80 | 24-26 | 6.0-8.0 | I-3-5 | <0.50 | I-0.24-0.32 |

| 34CRONImo6 | I-0.3-0.38 | 0.5-0.8 | ≤.025 | ≤.035 | I-0.4 | 1.3-1.7 | 1.3-1.7 | I-0.15-0.3 | / | / |

| I-16mnd | I-0.13-0.20 | 1.2-1.6 | ≤0.030 | ≤0.030 | I-0.17-0.37 | ≤0.30 | ≤0.30 | / | / | / |

| 20mmo | I-0.17-0.23 | 1.1-1.4 | ≤0.025 | ≤0.015 | I-0.17-0.37 | ≤0.030 | ≤0.030 | I-0.20-0.35 | / | / |

| 20mmono | I-0.16-0.23 | 1.2-1.5 | ≤0.035 | ≤0.035 | I-0.17-0.37 | / | / | I-0.45-0.60 | / | I-0.20-0.45 |

| Ipropathi yoomatshini | Dia. (Mm) | I-TS / RM (MPA) | YS / RP0.2 (MPA) | I-EL / A5 (%) | Ra / z (%) | I-notch | Amandla efuthe | I-HBW |

| I-A182 F51 | / | ≥620 | ≥450 | ≥25 | > 45 | V | ≥45J | / |

| I-A182 F53 | / | ≥800 | ≥550 | ≥15 | / | V | / | <310 |

| 34CRONImo6 | Ф12.5 | ≥785 | / | ≥11 | ≥30 | V | ≥71J | / |

| I-16mnd | Ф10 | I-470-630 | ≥345 | ≥21 | / | V | / | / |

| 20mmo | Ф10 | ≥605 | ≥475 | ≥25 | / | V | ≥180 | / |

| 20mmono | Ф10 | ≥635 | ≥490 | ≥15 | / | U | ≥47 | 187-229 |

Inkqubo yemveliso:

I-Command Fight Ukuhamba komgangatho: I-Steed Steeles kwiWerehouse (Vavanya i-Shemical) → Uvavanyo lobushushu) Ukuhlolwa (ubukhulu) → Ukupakisha kunye nokumakisha (isitampu sensimbi, uphawu)

Inzuzo:

Iipropathi ezibalaseleyo zoomatshini,

Ukunyamezelana okuphezulu kokufanelekileyo,

Lawula inkqubo yokuvelisa ngokungqongqo,

Izixhobo eziphambili zemveliso kunye nezixhobo zokuhlola,

Ubuntu obuhle bobuchwephesha,

Veza ubukhulu obahlukeneyo obusekwe kwiimfuno zomthengi,

Nika ingqalelo kukhuseleko lwephakheji,

Inkonzo epheleleyo esemgangathweni.

Amashishini okuSebenzisa:

Izixhobo zeMetelgaljeal, izixhobo zemigodi, iinqanawa ezilahweni, izixhobo zokuphakamisa, oomatshini bokwakha, ukuvelisa amandla, njl.