Best Price on Socket Welding - Forged Blocks – DHDZ

Best Price on Socket Welding - Forged Blocks – DHDZ Detail:

Open Die Forgings Manufacturer In China

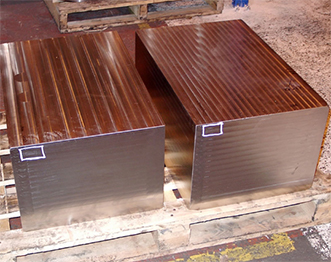

Forged Block

Forged blocks are of higher quality than plate due to the block having forging reduction on all four to six sides if required by the application. This will produce a refined grain structure which will assure the absence of defects and material soundness. Maximum forged block dimensions depend on material grade.

Common used material: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 | 42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV

FORGED BLOCK

Large press forged blocks up to 1500mm x 1500mm section with variable length.

Block forging tolerance typically -0/+3mm up to +10mm dependent on size.

All Metals has the forging capabilities to produce bars from the following alloy types:

● Alloy steel

● Carbon steel

● Stainless steel

FORGED Block CAPABILITIES

Material

MAX WIDTH

MAX WEIGHT

Carbon, Alloy Steel

1500mm

26000 kgs

Stainless Steel

800mm

20000 kgs

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., as an ISO registered certified forging manufacturer, guarantee that the forgings and/or bars are homogenous in quality and free of anomalies which are detrimental to the mechanical properties or machining properies of the material.

Case: Steel Grade C1045

|

Chemical composition % of steel C1045 (UNS G10450) |

|||

|

C |

Mn |

P |

S |

|

0.42-0.50 |

0.60-0.90 |

max 0.040 |

max 0.050 |

Applications

Valve bodies, hydraulic manifolds, pressure vessel components, mounting blocks, machine tool components, and turbine blades

Delivery form

Square bar, offset square bar , forged block.

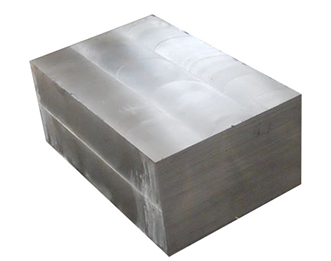

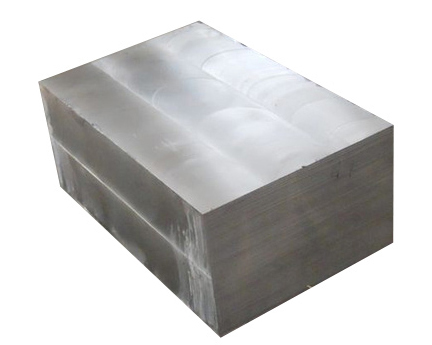

C 1045 Forged Block

Size: W 430 x H 430 x L 1250mm

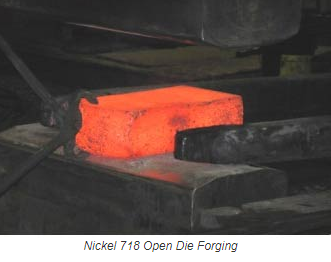

Forging (Hot Work ) Practice, Heat Treatment Procedure

|

Forging |

1093-1205℃ |

|

Annealing |

778-843℃ furnace cool |

|

Tempering |

399-649℃ |

|

Normalizing |

871-898℃ air cool |

|

Austenize |

815-843℃ water quench |

|

Stress Relieve |

552-663℃ |

| Rm - Tensile strength (MPa) (N+T) |

682 |

| Rp0.2 0.2% proof strength (MPa) (N +T) |

455 |

| A - Min. elongation at fracture (%) (N +T) |

23 |

| Z - Reduction in cross section on fracture (%) (N +T) |

55 |

| Brinell hardness (HBW): (+A) | 195 |

ADDITIONAL INFORMATION

REQUEST A QUOTE TODAY

OR CALL: 86-21-52859349

Product detail pictures:

Related Product Guide:

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Best Price on Socket Welding - Forged Blocks – DHDZ , The product will supply to all over the world, such as: Mauritania, Iran, United Arab emirates, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.