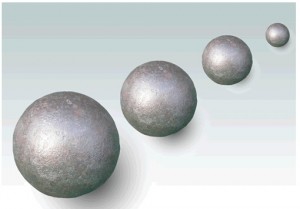

Rolling Steel Balls

Basic Info Of Rolling Steel Balls

| Product Name: | Hot-rolled Grinding Media Balls | ||

| Size Range: | OD 20mm-150mm | Raw Material: | B2 B3 B4 B6 |

| Process: | Hot-rolled | Breakage Rate: | <0.5% |

| Impact Toughness: | >15J/cm² | Impact to broken: | more than 18000 times |

| Surface Hardness: | 58-65HRC | Volume Hardness: | 56-63 HRC |

| Advantages: | Strong ToughnessGood Wear ResistantHigh Efficient Impact ResistantFully Automated Production Line | ||

| HS Code: | 732591(73261100待定) | Origin: | China |

| Application: | Ball Mill, Sag Mills, Vertimills, Mineral Process | ||

| Package: | Steel Druns & Flexible Cantainer Bags | ||

| Customization: | Available and Acceptable | Production Capacity: | 20000ton/Month |

Steel Ball Classification and Chemical Composition

| Material | C% | Si% | Mn% | Cr% | P% | S% |

| B2 | 0.75-0.85 | 0.17-0.37 | 0.70-0.85 | 0.50-0.60 | ≤0.020 | ≤0.020 |

| B3 | 0.56-0.66 | 0.20-0.37 | 0.75-0.90 | 0.80-1.10 | ≤0.020 | ≤0.020 |

| B6 | 0.70-0.85 | 0.20-0.30 | 0.85-1.10 | 0.80-1.10 | ≤0.020 | ≤0.020 |

Grinding balls are the most important part of today's crushing industry and bearing industry. Rolled steel balls have high hardness and good wear resistance, and the amount of raw materials used in production is small. Hot-rolled steel balls manufactured by rotary cutting and rolling forging have the advantages of fast delivery, large output and stable quality, and are especially suitable for long-term purchases by large mining groups. Hot-rolled steel balls have replaced traditional cast steel balls as the main grinding material for large semi-autogenous mills. Mineral powder manufacturers have gradually switched to rolling steel balls.

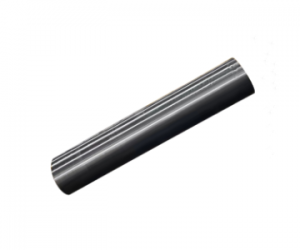

Production Process Of Rolling Steel Balls

1. Select the appropriate size round bar material. After passing the inspection, the round steel bar is cut into the required length of material according to the order requirements.

2. Heating the cut steel bars to a suitable temperature through a continuous heating furnace.

3. The heated raw material is sent into the steel ball rolling mill, and the raw material is rolled into a spherical shape. Each steel ball mill can roll out 60-360 steel ball blanks per minute.

4. Immediately put the steel ball blank into the specially designed online heat treatment equipment of our factory for quenching-tempering heat treatment, so that the steel ball can obtain high and uniform hardness.

5. After cooling, the products that pass the inspection are sent to the finished product warehouse for packaging and delivery. Material Inspection → Heating → Shaping by rolling → Hardneing treatment →Tempering to improve the performance → Quality assessment → Packing → Delivery

Application Area Of Rolling Steel Balls

Rolling steel balls are mainly used in mines , power plants , cement plants, steel plants , silica san plants ,coal chemical industry and other fields . World-renowned Mining Group China Minmetals , Shandong Gold , ZIJIN Mining , China National Gold, BHP, Codelco, Rio Tinto,Vale,Oyu Tolgoi ,etc.

Welcome to contact us DHDZ for customized wear-resistant material solutions !