A fagen aikin injiniyan bututun, flanges, a matsayin mahimman abubuwan haɗin bututun, suna da nau'ikan nau'ikan iri da ayyuka iri-iri. Daga cikin su, butt welded flanges sun zama "kayayyakin tauraro" a cikin tsarin bututun masana'antu saboda kyakkyawan aiki da yanayin aikace-aikacen fa'ida.

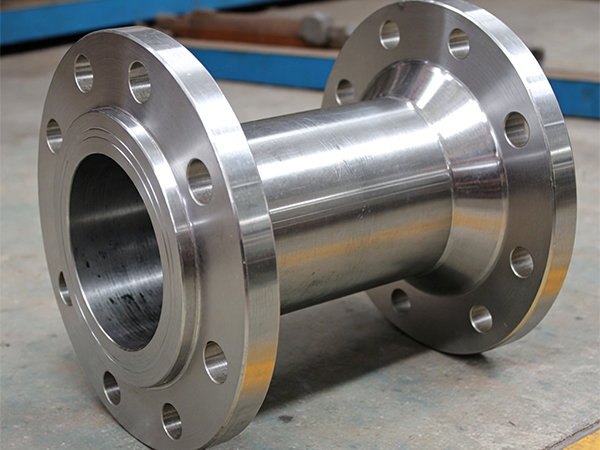

Flange waldi, wanda kuma aka sani da babban wuyansa flange, na musamman ne a cikin cewa dogon wuyan wuyansa mai tsayi yana fitowa daga wurin waldawa tsakanin flange da bututu (kamar yadda aka nuna a cikin zane-zane). Zane mai wayo na wannan babban wuyansa ba wai kawai yana haɓaka tsauri da ƙarfin flange ba, amma kuma yana sauƙaƙe ƙarancin damuwa, yana tabbatar da kwanciyar hankali da hatimin flange a cikin matsananciyar matsananciyar matsananciyar zafi, yanayin zafi, ko yanayin zafi. Tsarin rami na ciki ya ɗan fi girma fiye da diamita na waje na bututun, yana sauƙaƙa don waldawar butt, yayin da shingen walda mai kewaye ya mamaye ciki da waje na flange, yana ƙara haɓaka aikin rufewa.

Saboda waɗannan fa'idodin ƙira, flanges ɗin butt ɗin welded sun dace musamman don matsanancin matsin lamba, yanayin zafi, ko ƙarancin zafi a cikin filayen masana'antu kamar man fetur, sinadarai, da ginin jirgi. Zai iya jure wa matsanancin matsin lamba da zafin jiki, yana tabbatar da kwanciyar hankali na aikin bututun. A halin yanzu, ana amfani da flanges masu waldaran butt a cikin bututun don jigilar abubuwa masu ƙonewa, fashewar abubuwa, ko kafofin watsa labarai masu guba, kuma amintaccen aikin rufewar su yana ba da garanti mai ƙarfi don amintaccen jigilar kafofin watsa labarai.

Dangane da ƙa'idodin masana'anta, flanges ɗin welded dole ne su bi ƙaƙƙarfan buƙatu kamar JB4726-4728. Dangane da nau'ikan matsi da kayan ƙirƙira, ƙirjin ƙirƙira sun bambanta daga Grade I zuwa Grade III don tabbatar da aikin flange a wurare daban-daban na aiki. Bugu da ƙari, gangaren waje na wuyan welded flange kada ya wuce 70 °. Wannan dalla-dalla na ƙira yana taimakawa sosai don sarrafa sigogin fasaha yayin samarwa da hanyoyin walda, cikakken amfani da rawar da ƙimar flange.

Lokacin aikawa: Maris 25-2025