Litaba tsa indasteri

-

Ke eng e lokelang ho ntlafatsoa ts'ebetsong ea tlhahiso ea likarolo tsa forging

Tšebelisong ea kajeno ea likarolo tsa forging, haeba taolo ea mocheso e le mpe kapa e sa tsotelleng e tla baka letoto la liphoso ts'ebetsong ea tlhahiso, sena se tla fokotsa boleng ba likarolo tsa forging, e le ho felisa likarolo tsa forging tsa sekoli sena, ea pele ea ho ntlafatsa likarolo tsa tšepe, ka ...Bala haholoanyane -

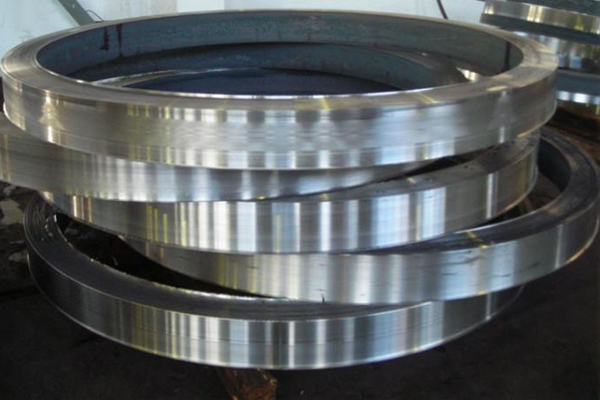

Lintlha tse susumetsang tekanyo ea tšebeliso ea flange

Tabeng ea mahoashe a tloaelehileng a li-flanges, limaraka tse fapaneng tsa tšepe le mekhoa e fapaneng ea matsoelintsoeke li na le likhato tse fapaneng tsa ho fokotsa mokhathala, joalo ka tekanyo e fokolang ea li-coil flanges tse chesang li nyane ho feta li-coil flange tse chesang.Boitlhakiso bo bontša hore cadmium plating e ka eketsa mokhathala haholo ...Bala haholoanyane -

Mekhoa ea ho futhumatsa le ho futhumatsa bakeng sa ho forging tšepe e sa hloekang

Ho ea ka lebelo le fapaneng la ho pholile, ho na le mekhoa e meraro ea ho pholile ea lisebelisoa tsa tšepe tse sa hloekang: ho pholile moeeng, lebelo la ho pholisa le potlakile;Sekhahla sa ho pholisa se lieha lehlabatheng la lime.Seboping se pholileng, lebelo la ho pholisa le lieha haholo.1. Ho pholile moeeng, lintho tse entsoeng ka tšepe e sa hloekang ka mor'a forgin ...Bala haholoanyane -

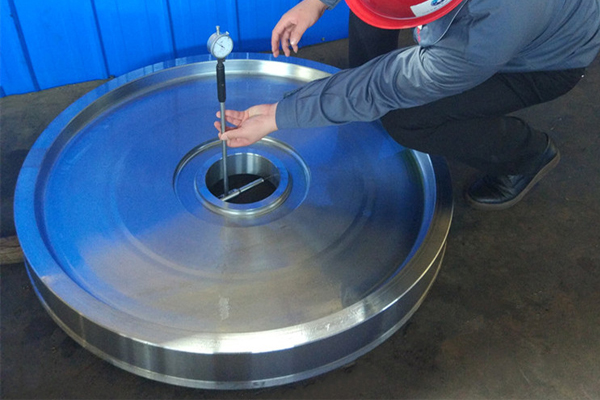

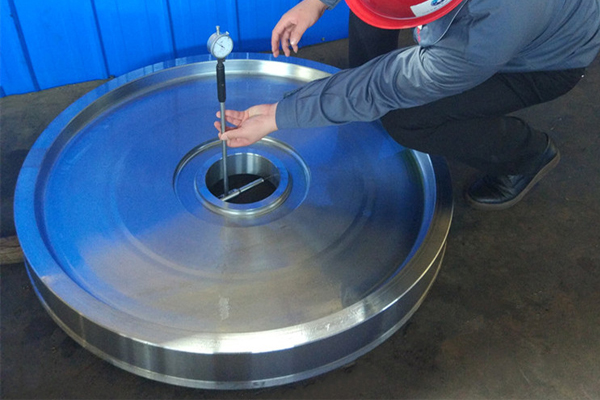

Tlhahlobo ea boleng ba ponahalo ea forgings

Tlhahlobo ea boleng ba ponahalo ka kakaretso ke tlhahlobo e sa senyeheng, hangata ka leihlo le hlobotseng kapa tlhahlobo e tlase ea khalase e khanyang, ha ho hlokahala, hape sebelisa mokhoa o sa senyeheng oa tlhahlobo.Mekhoa ea tlhahlobo ea boleng ba kahare ba forgings e boima e ka akaretsoa joalo ka: mokhatlo oa macroscopic ...Bala haholoanyane -

Ke eng eo re lokelang ho e ela hloko mabapi le polokeho nakong ea ts'ebetso ea forging?

Nakong ea ts'ebetso ea ho qhekella, mabapi le ts'ireletso, re lokela ho ela hloko: 1. tlhahiso ea ho forging e etsoa ka boemo ba tšepe e tukang (mohlala, 1250 ~ 750 ℃ mefuta e mengata ea mocheso o tlaase oa carbon steel), ka lebaka la lintho tse ngata. ea mosebetsi oa matsoho, ho chesoa ka phoso ho ka etsahala.2. Ho futhumala ha f...Bala haholoanyane -

Forging: Mokhoa oa ho etsa forgings tse ntle?

Hona joale lisebelisoa tse sebelisoang indastering hangata li sebelisa mokhoa oa ho forging, DHDZ e fana ka lisebelisoa tsa boleng bo phahameng, joale ha ho etsoa, ho sebelisoa lisebelisoa life tse tala?Lisebelisoa tsa ho qhekella haholo-holo ke tšepe ea carbon le alloy steel, e lateloa ke aluminium, magnesium, koporo, titanium le lisebelisoa tsa tsona.Boemo ba pele ba ...Bala haholoanyane -

Ke eng eo re lokelang ho e ela hloko mabapi le polokeho nakong ea ts'ebetso ea forging?

Nakong ea ts'ebetso ea ho qhekella, mabapi le ts'ireletso, re lokela ho ela hloko: 1. tlhahiso ea ho forging e etsoa ka boemo ba tšepe e tukang (mohlala, 1250 ~ 750 ℃ mefuta e mengata ea mocheso o tlaase oa carbon steel), ka lebaka la lintho tse ngata. ea mosebetsi oa matsoho, ho chesoa ka phoso ho ka etsahala.2. Ho futhumala ha f...Bala haholoanyane -

Na ho na le tlhoko ea ho thatafala ha shaft forgings?

Ho thatafala ha sefahleho le ho tšoana ha shaft forgings ke lintho tsa mantlha tsa litlhoko tsa tekheniki le tlhahlobo e tloaelehileng.Ho thatafala ha 'mele ho bonts'a khanyetso ea ho roala, joalo-joalo, tlhahisong, lebopo la resilience D boleng ba boima ba HSd bo sebelisetsoa ho hlalosa.Litlhoko tsa boima ba shaft forgings...Bala haholoanyane -

Licheke tsa boleng ba forgings ke life?

E le ho etsa bonnete ba hore boleng ba forgings ho finyella litlhoko tsa moralo le tšebeliso ea litsupa, hoa hlokahala ho etsa tlhahlobo ea boleng (lihlahisoa tse se nang letho, tse felileng le lihlahisoa tse felileng).Likahare tsa tlhahlobo ea boleng ba forgings li kenyelletsa: tlhahlobo ea sebopeho sa lik'hemik'hale, appe ...Bala haholoanyane -

Lintlha tseo u lokelang ho li ela hloko ha u sebelisa li-flange tse nang le likhoele

Flange e nang le khoele e bolela lesela le hoketsoeng ka khoele le phala.Nakong ea moralo, e ka sebetsanoa ho ea ka flange e hlephileng.Molemo ke hore ha ho na welding e hlokahalang, 'me torque e eketsehileng e hlahisoang ke deformation ea flange holim'a silinda kapa phala e nyenyane haholo.Bothata ke hore t...Bala haholoanyane -

Ke hobane'ng ha u khetha 304 butt welded steel stainless flanges?

Ha re qale ka 'nete: Lipeipi tsa tšepe tse sa hloekang tsa Austenitic li sebelisoa hangata libakeng tse fapaneng tse senyang.Leha ho le joalo, haeba u le hlokolosi, u tla fumana hore litokomaneng tsa moralo oa likarolo tse ling, ha feela DN≤40, mefuta eohle ea thepa e amoheloa.Litokomaneng tsa moralo oa tse ling ...Bala haholoanyane -

Mokhoa oa ho khetholla boleng ba ho forging

Mosebetsi o ka sehloohong oa tlhahlobo ea boleng ba forgings le tlhahlobo ea boleng ke ho tseba boleng ba forgings, ho sekaseka lisosa tsa mefokolo ea forgings le mehato ea thibelo, tlhahlobo le lipatlisiso Ke mokhoa oa bohlokoa oa ho ntlafatsa le ho netefatsa boleng ba forgings ho batlisisa lisosa tsa ts'ireletso. ...Bala haholoanyane