Ma Bars Opanga

Open Die Forgings Wopanga Ku China

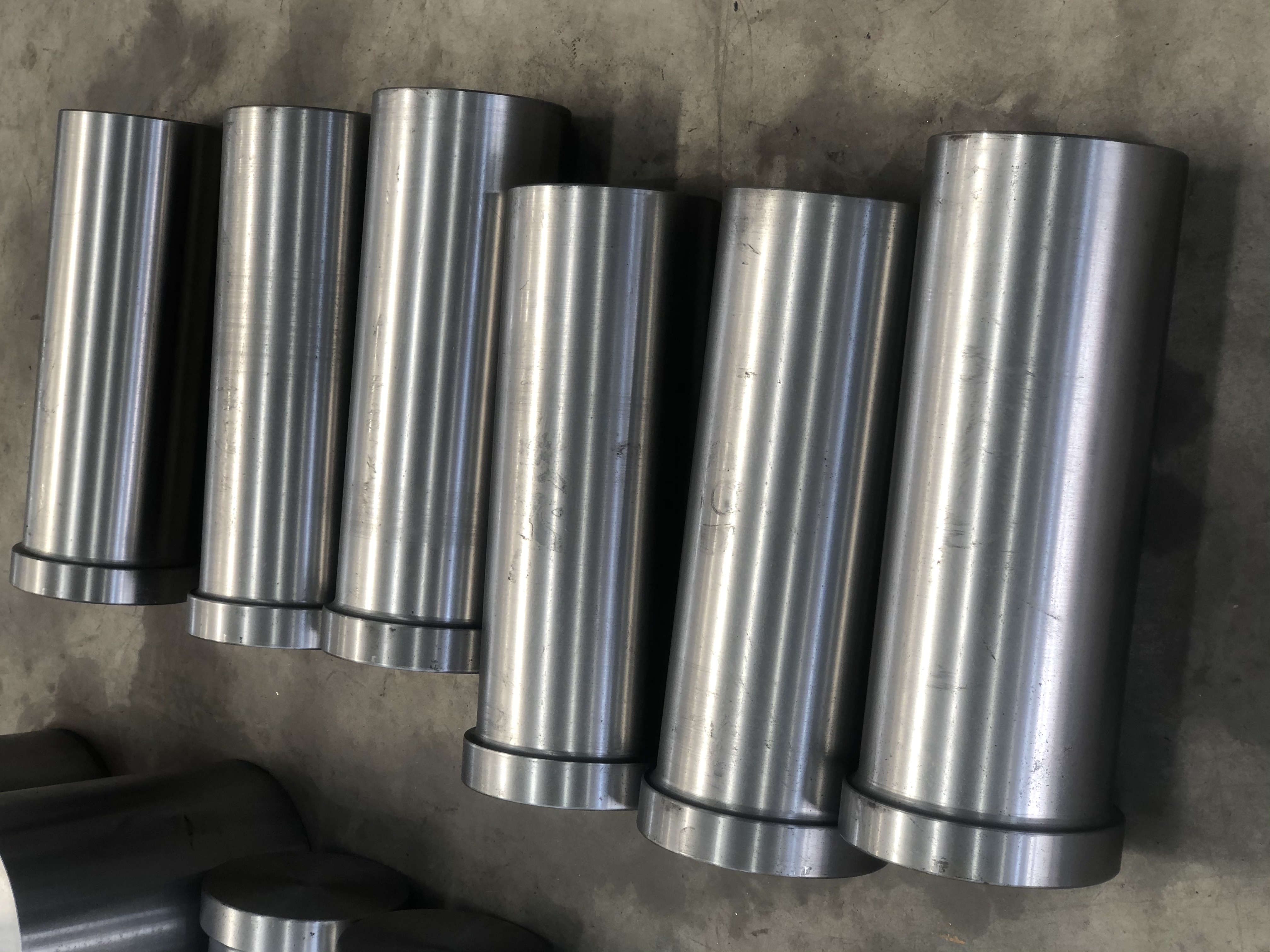

Ma Bars Opanga

Zomwe zimagwiritsidwa ntchito nthawi zambiri: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV12

ZINTHU ZOPHUNZITSIDWA ZA BAL

Mipiringidzo yozungulira, mipiringidzo ya Square, mipiringidzo ya Flat ndi mipiringidzo ya Hex. Zitsulo Zonse zili ndi mphamvu zopangira kupanga mipiringidzo kuchokera kumitundu ya alloy:

● Chitsulo chachitsulo

● Chitsulo cha carbon

● Chitsulo chosapanga dzimbiri

ZOPHUNZITSA ZA BARAKA

ALLOY

MAX WIDTH

MAX WIGHT

Carbon, Aloyi

1500 mm

26000 kg

Chitsulo chosapanga dzimbiri

800 mm

20000 kgs

ZOPHUNZITSA ZA BARAKA

Kutalika kwakukulu kwa mipiringidzo yozungulira yopangidwa ndi hex ndi 5000 mm, ndi kulemera kwakukulu kwa 20000 kgs.

Kutalika ndi m'lifupi kwa mipiringidzo lathyathyathya ndi mipiringidzo lalikulu ndi 1500mm, ndi kulemera pazipita 26000 kgs.

A bala lopukutira kapena chopiringizikaamapangidwa ndi kutenga ingot ndikupangampaka kukula kwake, kawirikawiri, awiri otsutsana amafa. Zitsulo zopukutira zimakhala zamphamvu, zolimba komanso zolimba kuposa mawonekedwe opangidwa kapena zida zamakina. Mutha kupeza kapangidwe kambewu kakang'ono m'magawo onse a forgings, ndikuwonjezera magawo kuti athe kupirira kumenyana ndi kuvala.

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., Monga ISO yolembetsa yovomerezeka yopangira zida, zimatsimikizira kuti forgings ndi / kapena mipiringidzo ndi yofanana mumtundu komanso yopanda anomalies yomwe imawononga zinthu zamakina kapena machining azinthu.

Mlandu:

Kalasi yachitsuloEN 1.4923 X22CrMoV12-1

KapangidweMartensitic

| Chemical kapangidwe% zitsulo X22CrMoV12-1 (1.4923): EN 10302-2008 | ||||||||

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.18 - 0.24 | pa 0.5 | 0.4 - 0.9 | 0.3 - 0.8 | kukula 0.025 | kukula 0.015 | 11 - 12.5 | 0.8 - 1.2 | 0.25 - 0.35 |

Mapulogalamu

Powerplant, Makina opanga makina, Kupanga magetsi.

Zigawo za mizere ya mapaipi, ma boilers a nthunzi ndi ma turbines.

Fomu yobweretsera

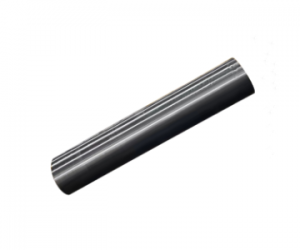

Mipiringidzo yozungulira, mphete zozungulira, zozungulira, X22CrMoV12-1 bar

Kukula: φ58x536L mm.

Kuchita (Hot Work) Kuchita

Zida zimayikidwa mu ng'anjo ndikutenthedwa. Kutentha kukafika 1100 ℃, chitsulo chimapangidwa. Amatanthawuza njira iliyonse yamakina yomwe imapanga zitsulo zopangira chitsulo chimodzi kapena zingapo zikafa, mwachitsanzo, kutsegula / kutsekedwa kufa, kutulutsa, kugudubuza, etc. Panthawi imeneyi, kutentha kwachitsulo kumagwa. Ikatsika mpaka 850 ℃, chitsulo chimatenthedwanso. Kenako bwerezani ntchito yotentha pa kutentha kokwezeka (1100 ℃). Chiŵerengero chochepa cha chiŵerengero cha ntchito yotentha kuchokera ku ingot kupita ku billet ndi 3 mpaka 1.

Njira Yochizira Kutentha

Kwezani zinthu preheat mankhwala Machining mu kutentha mankhwala furance. Kutentha mpaka 900 ℃. Kuphika pa kutentha kwa maola 6 kwa mphindi 5. Mafuta azimitsa ndi kutentha pa 640 ℃. Kenako Air-cool.

Makina amakina a X22CrMoV12-1 bar forged (1.4923).

| Rm- Mphamvu yamanjenje (MPa) (+QT) | 890 |

| Rp0.20.2% mphamvu yotsimikizira (MPa) (+QT) | 769 |

| KV- Mphamvu zamphamvu (J) (+QT) | -60 ° 139 |

| A - Min. elongation pa fracture (%) (+QT) | 21 |

| Kuuma kwa Brinell (HBW): (+A) | 298 |

Magiredi aliwonse, kupatula omwe tawatchulawa, atha kupangidwa molingana ndi zomwe kasitomala amafuna.