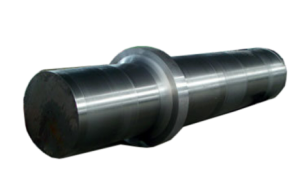

I-Forged Shaft

Vula Umkhiqizi We-Die Forgings E-China

I-SHAFT ENKOSHELWE / ISINYATHELO SHAFT/ SPINDLE / AXLE SHAFT

Izinkambu zesicelo ze-forgings shaft ziyi

Ama-shaft forgings (izingxenye zemishini) Ama-shaft forging yizinto eziyisilinda ezigqokwa phakathi ne-bearing noma phakathi nesondo noma phakathi negiya, kodwa ezimbalwa ziyizikwele. I-shaft iyingxenye yomshini esekela ingxenye ejikelezayo futhi izungezisa ngayo ukuze idlulise ukunyakaza, i-torque noma izikhathi zokugoba. Ngokuvamile, iwumumo wenduku yensimbi, futhi ingxenye ngayinye ingaba nobubanzi obuhlukile. Izingxenye zomshini ezenza ukunyakaza kwe-slewing zifakwe ku-shaft. Igama lesiShayina shaft forging uhlobo shaft, mandrel, drive shaft material ukusetshenziswa 1, carbon steel 35, 45, 50 kanye nezinye izinga okusezingeni carbon steel kwesakhiwo ngenxa izici zayo eliphezulu olunzulu mechanical, izicelo ngaphezulu, okuyinto 45 steel isetshenziswa kabanzi. Ukuze uthuthukise izakhiwo zayo zemishini, ukujwayelekile noma ukucisha kanye nokushisa kufanele kwenziwe. Kumashafu esakhiwo angabalulekile noma anamandla aphansi, izinsimbi ze-carbon structural ezifana ne-Q235 ne-Q275 zingasetshenziswa. I-2, insimbi ye-alloy Insimbi ye-alloy inezakhiwo eziphakeme zemishini, kodwa intengo ibiza kakhulu, isetshenziselwa kakhulu ama-shafts anezidingo ezikhethekile. Isibonelo, ama-shaft anesivinini esikhulu asebenzisa ama-sliding bearings, ngokuvamile asetshenziswa i-low-carbon alloy structural steels njenge-20Cr kanye ne-20CrMnTi, angathuthukisa ukumelana nokugqokwa kwejenali ngemva kokungcwatshwa kwe-carburizing kanye nokucisha; i-rotor shaft ye-turbo generator isebenza ngaphansi kokushisa okuphezulu, isivinini esikhulu kanye nezimo zomthwalo osindayo. Ngezakhiwo ezinhle zemishini yokushisa okuphezulu, izinsimbi ze-alloy structural ezifana ne-40CrNi kanye ne-38CrMoAlA zivame ukusetshenziswa. I-blank of the shaft ikhethwa ukwakhiwa, kulandelwa insimbi eyindilinga; ngezakhiwo ezinkulu noma eziyinkimbinkimbi, insimbi ekhonjiwe noma i-ductile iron ingacatshangelwa. Isibonelo, ukwakhiwa kwe-crankshaft kanye ne-camshaft kusuka ku-ductile iron kunezinzuzo zezindleko eziphansi, ukumuncwa okuhle kokudlidliza, ukuzwela okuphansi ekugxilweni kwengcindezi, namandla amahle. Imodeli yemishini ye-shaft yi-beam, ejikeleziswa kakhulu, ngakho-ke ukucindezeleka kwayo kuvame umjikelezo we-symmetric. Izindlela zokwehluleka okungenzeka zihlanganisa ukuphuka kokukhathala, ukuphuka komthwalo omningi, kanye nokuwohloka okunwebeka ngokweqile. Ezinye izingxenye ezinamahabhu zivame ukufakwa ku-shaft, ngakho-ke ama-shaft amaningi kufanele enziwe ama-shaft anyathelwe ngenani elikhulu lomshini. Ukuhlukaniswa Kwesakhiwo Idizayini Yesakhiwo Idizayini yesakhiwo yeshafti iyisinyathelo esibalulekile ekunqumeni ukuma okunengqondo kanye nobukhulu besakhiwo beshaft. Iqukethe uhlobo, usayizi kanye nendawo yengxenye efakwe ku-shaft, indlela ingxenye egxilwe ngayo, imvelo, isiqondiso, ubukhulu nokusabalalisa komthwalo, uhlobo nobukhulu bokuthwala, indawo engenalutho ye-shaft, inqubo yokukhiqiza kanye nokuhlanganisa, ukufakwa nokuthutha, umgodi Ukuguquguquka kanye nezinye izici zihlobene. Umklami angakwazi ukuklama ngokuvumelana nezidingo ezithile ze-shaft. Uma kunesidingo, izikimu eziningana zingaqhathaniswa ukuze ukhethe umklamo ongcono kakhulu.

Okulandelayo yizimiso zokuklama isakhiwo seshaft jikelele

1. Yonga izinto ezisetshenziswayo, yehlisa isisindo, futhi usebenzise umumo wamandla alinganayo. Umumo we-coefficient wesigaba esinqamulayo sobukhulu noma esikhulu.

2, kulula ukuyibeka ngokunembile, ukuzinzisa, ukuhlanganisa, ukuqaqa futhi ulungise izingxenye ku-shaft.

3. Sebenzisa izindlela ezehlukene zesakhiwo ukuze unciphise ukugxilisa ingqondo nokuthuthukisa amandla.

4. Kulula ukwenza nokuqinisekisa ukunemba.

Ukuhlukaniswa kwama-shaft Amashafu avamile angahlukaniswa abe ama-crankshaft, ama-shaft aqondile, ama-flexible shafts, ama-shaft aqinile, ama-hollow shafts, ama-shaft aqinile, kanye nama-flexible shafts (ama-flexible shafts) kuye ngokuthi ukwakheka kwe-shaft kunjani.

I-shaft eqondile ingabuye ihlukaniswe ibe

1 shaft, engaphansi kokubili kokugoba kanye ne-torque, futhi iwumshini ovame kakhulu emishinini, njengamashafti kwizinciphisi zejubane ezihlukahlukene.

2 mandrel, esetshenziselwa ukusekela izingxenye ezijikelezayo kuphela ukuthwala isikhashana ukugoba ngaphandle kokudlulisa torque, ezinye mandrel ukuzungeza, ezifana eseli yesitimela imoto, njll, ezinye mandrel ayizungezi, ezifana kushaft ukusekela pulley.

I-3 Transmission shaft, esetshenziselwa ukudlulisa i-torque ngaphandle komzuzu wokugoba, njenge-axis ende yokubona kumshini wokuhambisa u-crane, shaft yokushayela yemoto, njll.

Impahla ye-shaft ikakhulukazi i-carbon steel noma i-alloy steel, futhi i-ductile iron noma i-alloy cast iron nayo ingasetshenziswa. Amandla okusebenza we-shaft ngokuvamile ancike emandleni nokuqina, futhi isivinini esikhulu sincike ekuzinzeni kokudlidliza. Isicelo sohlelo Lokusebenza Ukuqina kwe-torsional Ukuqina kwe-torsional ye-shaft kubalwa njengenani lokuguquguquka kokuguquguquka kwe-shaft ngesikhathi sokusebenza, kukalwa ngokwe-engeli yokuguquguquka imitha ngayinye yobude be-shaft. Ukuguqulwa kwe-torsional ye-shaft kufanele kuthinte ukusebenza nokunemba kokusebenza komshini. Isibonelo, uma i-angle ye-torsion ye-camshaft yenjini evuthayo yangaphakathi inkulu kakhulu, izothinta isikhathi esifanele sokuvula nokuvala kwe-valve; i-torsion angle ye-transmission shaft ye-gantry crane motion mechanism izothinta ukuvumelanisa kwesondo lokushayela; Kudingeka ukuqina okukhulu kwe-torsional kumashafti asengozini yokudlidliza kwe-torsional kanye nama-shaft ohlelweni lokusebenza.

Izidingo zobuchwepheshe 1. Ukunemba komshini

1) Ukunemba kwe-Dimensional Ukunemba kwe-dimensional kwezingxenye ze-shaft ikakhulukazi kubhekisela kububanzi nokunemba kwe-dimensional kwe-shaft kanye nokunemba kwe-dimensional kobude be-shaft. Ngokwezidingo zokusetshenziswa, ukunemba kobubanzi bejenali eyinhloko kuvamise ukuba yi-IT6-IT9, kanti ijenali yokunemba nayo ifika ku-IT5. Ubude be-shaft ngokuvamile buchazwa njengosayizi wegama. Ngobude besinyathelo ngasinye se-shaft stepped, ukubekezelelana kunganikezwa ngokuvumelana nezidingo zokusetshenziswa.

2) Ukunemba kweJiyomethri Izingxenye zeshaft ngokuvamile zisekelwa kumajenali amabili. Lawa majenali amabili abizwa ngokuthi amajenali asekelayo futhi ayireferensi yomhlangano we-shaft. Ngaphezu kokunemba kwe-dimensional, ukunemba kwejometri (ukuyindilinga, isilinda) kwejenali esekelayo ngokuvamile kuyadingeka. Kumajenali wokunemba okuvamile, iphutha lejometri kufanele likhawulelwe ekubekezeleleni kobubanzi. Uma izidingo ziphakeme, amanani okubekezelela avunyelwe kufanele acaciswe engxenyeni yomdwebo.

3) Ukunemba kokuma okuhlangene Ukubumbana phakathi kwamajenali okukhwelana (amajenali amalungu okushayela ahlangene) ezingxenyeni ze-shaft ngokuhlobene namajenali asekelayo kuyisidingo esivamile sokunemba kwawo okuhambisanayo. Ngokuvamile, i-shaft enembayo evamile, ukunemba okufanayo ngokuphathelene nokuphuma kwe-radial kwejenali yokusekela ngokuvamile ingu-0.01-0.03 mm, futhi i-shaft enembayo ephezulu ingu-0.001-0.005 mm. Ukwengeza, ukunemba kwe-mutual positional kubuye kube yi-coaxiality yezindawo ze-cylindrical zangaphakathi nangaphandle, i-perpendicularity yobuso bokuphela obubekwe nge-axially kanye nomugqa we-axial, nokunye okunjalo. 2, ubuhwaqane bobuso Ngokusho kokunemba komshini, isivinini sokusebenza, izidingo zokuqina kwezingxenye ze-shaft nazo zihlukile. Ngokuvamile, ubulukhuni obuphezulu be-Ra yejenali esekelayo yi-0.63-0.16 μm; ubulukhuni obuphezulu u-Ra wejenali ehambisanayo ngu-2.5-0.63 μ m.

Ubuchwepheshe bokucubungula 1, ukukhethwa kwezingxenye ze-shaft ezibonakalayo zezingxenye ze-shaft, Ikakhulukazi ngokusekelwe emandleni, ukuqina, ukumelana nokugqoka kanye nenqubo yokukhiqiza ye-shaft, nokulwela umnotho.

Izinto ezisetshenziswayo ezijwayelekile: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 |22NiCrMoV|EN 1.4201 |42CrMo4

UMSHATI ONGATHIWE

I-Shaft Forged Enkulu ifika ku-30 T.. Ukubekezelela indandatho ngokuvamile -0/+3mm kufika ku-+10mm kuye ngosayizi.

●Zonke izinsimbi zinamandla okubumba ukukhiqiza indandatho engumgunyathi kulezi zinhlobo ezilandelayo zengxubevange:

● Insimbi ye-alloy

●Insimbi yekhabhoni

●Insimbi engagqwali

AMAKHONO OMSHATI OQINIWE

Okubalulekile

MAX DIAMETER

ISISINDO ESIKHULU

I-Carbon, i-alloy Steel

1000mm

20000 kgs

Insimbi engagqwali

800mm

15000 kgs

I-Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., njengomkhiqizi womgunyathi oqinisekisiwe we-ISO obhalisiwe, iqinisekisa ukuthi ama-forging kanye/noma amabha ayafana ngekhwalithi futhi awanawo ama-anomalies alimaza izakhiwo zemishini noma izici zomshini zezinto .

Icala:

Ibanga LensimbiI-BS EN 42CrMo4

Imininingwane ye-BS EN 42CrMo4 Alloy Steel Ehlobene Nezilinganiso

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | 0.40 ubuningi | 0.035 ubuningi | 0.035 ubuningi | 0.90-1.20 | 0.15-0.30 |

| I-BS EN 10250 | Okubalulekile No. | I-DIN | I-ASTM A29 | I-JIS G4105 | BS 970-3-1991 | BS 970-1955 | AS 1444 | AFNOR | GB |

| 42CrMo4 | 1.7225 | 38HM | 4140 | I-SCM440 | 708M40 | EN19A | 4140 | 42CD4 | 42CrMo |

Ibanga lensimbi 42CrMo4

Izinhlelo zokusebenza

Ezinye izindawo ezijwayelekile zokufaka izicelo ze-EN 1.4021

Izingxenye zokumpompa kanye ne-Valve, i-Shafting, i-Spindels, izinti ze-Piston, okokufakwayo, ama-stirrers, ama-Bolts, amantongomane

I-TS EN 1.4021 Indandatho eyi-Forged , Izinsimbi zensimbi engagqwali zendandatho ye-Slewing

Usayizi: φ840 x L4050mm

Ukuqamba (Umsebenzi Oshisayo) Ukuzijwayeza, Inqubo Yokwelapha Ukushisa

| Ukuqamba | 1093-1205 ℃ |

| Anealing | 778-843 ℃ isithando somlilo esipholile |

| Ukuthuthumela | 399-649℃ |

| Ukujwayela | 871-898 ℃ umoya opholile |

| Austenize | 815-843 ℃ ukucisha amanzi |

| Yehlisa Ingcindezi | 552-663 ℃ |

| Ukucisha | 552-663 ℃ |

I-DIN 42CrMo4 I-alloy Steel Mechanical Properties

| Usayizi Ø mm | Isivuno sokucindezeleka | I-Ultimate tensile Stress, | Ukwelula | Ubulukhuni HB | Ukuqina |

| Rp0.2,N/nn2, imiz. | Rm,N/nn2 | A5,%, imiz. | KV, Joule, min. | ||

| <40 | 750 | 1000-1200 | 11 | 295-355 | 35 ngo-20ºC |

| 40-95 | 650 | 900-1100 | 12 | 265-325 | 35 ngo-20ºC |

| > 95 | 550 | 800-950 | 13 | 235-295 | 35 ngo-20ºC |

| I-Rm - Amandla e-Tensile (MPa) (Q +T) | ≥635 |

| I-Rp0.2 0.2% amandla obufakazi (MPa) (Q +T) | ≥440 |

| I-KV - Impact energy (J) (Q +T) | +20° |

| A - Min. Ubude ekwephukeni (%)(Q +T) | ≥20 |

| Z - Ukwehliswa kwesigaba esiphambene ekuqhekekeni (%)(N+Q +T) | ≥50 |

| Ukuqina kwe-Brinell (HBW): (Q +T) | ≤192HB |

ULWAZI OLWENGEZIWE

CELA I-QUOTE NAMUHLA

NOMA USHAYELE: 86-21-52859349