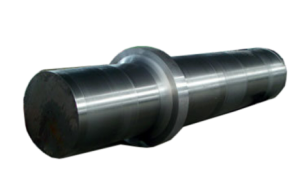

Karfe Shaft

Bude Die Forgings Manufacturer A China

FARUWA SHAFT / MATAKI SHAFT/ SPINDLE / AXLE SHAFT

Filin aikace-aikace na shingen ƙirƙira sune

Juzu'in na'ura (haɓaka na'urori) Ƙarfafa ƙirƙira abubuwa ne masu siliki waɗanda ake sawa a tsakiyar abin ɗaukar kaya ko a tsakiyar dabaran ko a tsakiyar injin, amma kaɗan suna da murabba'i. Shaft wani yanki ne na inji wanda ke goyan bayan juzu'in juzu'i kuma yana jujjuyawa dashi don watsa motsi, juzu'i ko lokacin lanƙwasawa. Gabaɗaya, siffar sandar ƙarfe ce, kuma kowane sashi na iya samun diamita daban-daban. An ɗora sassan injin da ke yin motsi na kashewa a kan shaft. Sin sunan shaft ƙirƙira irin shaft, mandrel, drive shaft abu amfani 1, carbon karfe 35, 45, 50 da sauran high quality-carbon tsarin karfe saboda da high m inji Properties, ƙarin aikace-aikace, wanda 45 karfe da aka yi amfani da mafi yadu. Don inganta kayan aikin injiniya, normalizing ko quenching da tempering ya kamata a yi. Don ginshiƙan tsarin da ba su da mahimmanci ko kuma suna da ƙananan ƙarfi, ana iya amfani da ƙarfe na tsarin carbon kamar Q235 da Q275. 2, gami karfe Alloy karfe yana da mafi girma inji Properties, amma farashin ne mafi tsada, mafi yawa amfani ga shafts da musamman bukatun. Misali, manyan igiyoyi masu saurin gudu ta amfani da igiyoyin zamiya, waɗanda aka saba amfani da su da ƙananan ƙarfe na ƙarfe na ƙarfe kamar 20Cr da 20CrMnTi, na iya haɓaka juriyar lalacewa na mujallar bayan carburizing da quenching; rotor shaft na turbo janareta aiki a karkashin high zafin jiki, high gudun da nauyi nauyi yanayi. Tare da kyawawan kaddarorin inji mai zafin jiki, ana amfani da manyan ƙarfe na ƙarfe kamar 40CrNi da 38CrMoAlA. An fi son blank na shaft don ƙirƙira, biye da karfe zagaye; don mafi girma ko hadaddun tsarin, za'a iya la'akari da simintin ƙarfe ko ƙarfe na ductile. Misali, ƙera crankshaft da camshaft daga baƙin ƙarfe na ductile yana da fa'idodin ƙarancin farashi, ingantaccen shawar girgiza, ƙarancin hankali ga maida hankali, da ƙarfi mai kyau. Samfurin injiniya na shaft shine katako, wanda yawanci yakan juya, don haka damuwa yawanci shine sake zagayowar ma'auni. Hanyoyin gazawa mai yuwuwa sun haɗa da karayar gajiya, karaya mai yawa, da nakasar naƙasa mai yawa. Wasu sassa tare da cibiyoyi yawanci ana shigar da su a kan shaft, don haka yawancin igiyoyi ya kamata a sanya su a cikin matakan da aka tako tare da adadi mai yawa na machining. Tsare Tsare Tsare Tsare Tsare Tsare Tsare Tsare Tsare-tsare mataki ne mai mahimmanci don tantance ma'auni mai ma'ana da kuma tsarin tsarin gaba ɗaya na ramin. Ya ƙunshi nau'i, girman da matsayi na ɓangaren da aka ɗora a kan shaft, hanyar da aka gyara sashi, yanayi, shugabanci, girman da rarraba kaya, nau'i da girman nauyin kaya, blank na shaft, tsarin masana'antu da haɗuwa, shigarwa da sufuri, shaft Nakasawa da sauran dalilai suna da alaƙa. Mai zane zai iya tsarawa bisa ga takamaiman bukatun shaft. Idan ya cancanta, ana iya kwatanta tsare-tsare da yawa don zaɓar mafi kyawun ƙira.

Wadannan su ne ka'idodin ƙirar tsarin shaft gaba ɗaya

1. Ajiye kayan, rage nauyi, da amfani da daidai-ƙarfi siffar. Girma ko babban sashe coefficient na giciye-sashe siffar.

2, mai sauƙi don daidaitaccen matsayi, daidaitawa, tarawa, rarrabawa da daidaita sassan akan shaft.

3. Yi amfani da matakan tsari daban-daban don rage yawan damuwa da inganta ƙarfi.

4. Mai sauƙin ƙira da tabbatar da daidaito.

Rarraba ramuka na yau da kullun ana iya raba su zuwa crankshafts, madaidaiciya madaidaiciya, madauri masu sassauƙa, ƙaƙƙarfan ramuka, ramukan ramuka, madaidaitan ramuka, da sassa masu sassauƙa (masu sassauƙa) dangane da tsarin tsarin ginin.

Za'a iya kara rarraba madaidaicin madaidaici

1 shaft, wanda aka yiwa duka biyun lokacin lanƙwasa da juzu'i, kuma shine mafi yawan shaft a cikin injuna, kamar shafts a cikin masu rage saurin gudu daban-daban.

2, wanda aka yi amfani da shi don tallafawa sassa masu jujjuya kawai don ɗaukar lokacin lanƙwasawa ba tare da isar da juzu'i ba, wasu jujjuyawar motsi, irin su axle na motar jirgin ƙasa, da sauransu, wasu daga cikin mandrel ba su jujjuya ba, irin su shaft ɗin da ke goyan bayan juyi.

3 Shaft na watsawa, galibi ana amfani dashi don watsa juzu'i ba tare da lankwasawa ba, kamar dogayen axis a cikin injin motsi na crane, tukin mota, da sauransu.

Abubuwan da ke cikin shaft ɗin sun fi ƙarfin carbon carbon ko ƙarfe ƙarfe, kuma ana iya amfani da baƙin ƙarfe mai ductile ko ƙarfe simintin ƙarfe. Ƙarfin aiki na shaft gabaɗaya ya dogara ne akan ƙarfi da taurin kai, kuma babban gudun ya dogara da kwanciyar hankali na girgiza. Aikace-aikacen Aikace-aikacen Trizonal ya hau gefen tsinkaye na shaft an lasafta shi azaman adadin yatsan turstormation na shakin yayin aiki, an auna shi cikin yanayin tasha mai tsayi. Nakasar juzu'i na shaft ya kamata ya shafi aiki da daidaiton aiki na injin. Alal misali, idan kusurwar torsion na camshaft na injin konewa na ciki ya yi girma sosai, zai shafi daidai lokacin buɗewa da rufewa na bawul; kusurwar torsion na shingen watsawa na injin motsi na crane na gantry zai shafi aiki tare da dabaran tuki; Ana buƙatar babban ƙaƙƙarfan ƙwanƙwasa don raƙuman ruwa waɗanda ke cikin haɗarin girgizawar girgizawa da igiyoyi a cikin tsarin aiki.

Bukatun fasaha 1. Machining daidaito

1) Daidaiton girman girman daidaitattun sassan sassan shaft galibi yana nufin diamita da daidaiton ma'auni na shaft da daidaiton girman tsayin shaft. Dangane da buƙatun amfani, daidaiton babban diamita yawanci IT6-IT9 ne, kuma madaidaicin mujallar ita ma tana zuwa IT5. Tsawon shaft yawanci ana bayyana shi azaman girman ƙima. Ga kowane tsayin tsayin tsayin tsayin daka, ana iya ba da haƙuri bisa ga buƙatun amfani.

2) Daidaiton Geometric Sassan Shaft gabaɗaya ana goyan bayan aikin ta mujallu biyu. Waɗannan mujallu guda biyu ana kiran su mujallolin tallafi kuma su ne maƙasudin taro na shaft. Baya ga daidaiton girma, ana buƙatar daidaiton lissafi (zagaye, cylindricity) na jarida mai goyan baya gabaɗaya. Don mujallolin daidaito na gabaɗaya, kuskuren lissafi ya kamata a iyakance ga juriyar diamita. Lokacin da buƙatun suka yi girma, ƙimar haƙuri da aka yarda ya kamata a ƙayyade akan zanen ɓangaren.

3) Daidaitaccen matsayi na juna Haɗin kai tsakanin mujallolin mating (mujallu na ma'aikatan da suka taru) a cikin sassan shaft dangane da mujallolin tallafi shine abin da ake bukata na kowa don daidaiton matsayi na juna. Gabaɗaya, madaidaicin madaidaicin al'ada, daidaitaccen madaidaicin dangane da radial runout na mujallar tallafi gabaɗaya 0.01-0.03 mm, kuma madaidaicin madaidaicin 0.001-0.005 mm. Bugu da ƙari, daidaiton matsayi na juna kuma shine coaxial na ciki da na waje cylindrical surfaces, da perpendicularity na axially matsayi karshen fuskoki da axial line, da makamantansu. 2, Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa ) ya yi. Gabaɗaya, ƙarancin ƙasa Ra na jarida mai goyan baya shine 0.63-0.16 μm; Rarraba saman Ra na jaridar da ta dace shine 2.5-0.63 μm.

Fasahar sarrafa kayan aiki 1, zaɓin sassan sassa na kayan ɓangarorin ɓangarorin ɓangarorin, Yafi dacewa da ƙarfi, ƙarfi, juriya da tsarin masana'anta na shaft, da ƙoƙarin tattalin arziki.

Abubuwan da aka saba amfani da su: 1045 | 4130 | 4140 | 4340 | 5120 | 8620 |42CrMo4 | 1.7225 | 34CrAlNi7 | S355J2 | 30NiCrMo12 | 22NiCrMoV| EN 1.4201 | 42CrMo4

RUWAN KARYA

Manyan jabun Shaft har zuwa 30 T.. Haƙurin jujjuyawar zobe yawanci -0/+3mm har zuwa +10mm ya dogara da girman.

●All Metals yana da damar ƙirƙira don samar da zobe na jabu daga nau'ikan gami masu zuwa:

● Ƙarfe na ƙarfe

● Karfe Karfe

● Bakin karfe

RUWAN KARYA SHAFT

Kayan abu

MAX DIAMETER

MAX AUNA

Carbon, Alloy Karfe

1000mm

20000 kgs

Bakin Karfe

800mm

15000 kg

Shanxi DongHuang Wind Power Flange Manufacturing Co., LTD., A matsayin ISO ƙwararren ƙirƙira ƙirƙira, yana ba da garantin cewa jabun da / ko sanduna sun yi kama da inganci kuma ba su da abubuwan da ba su da lahani waɗanda ke da illa ga kaddarorin injin ko kayan aikin injin.

Harka:

Karfe darajaTS EN 42CrMo4

TS EN 42CrMo4 Alloy Karfe Mahimman Bayanai da Kwatankwacinsu

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | 0.40 max | 0.035 max | 0.035 max | 0.90-1.20 | 0.15-0.30 |

| TS EN 10250 | Material No. | DIN | ASTM A29 | Saukewa: G4105 | BS 970-3-1991 | BS 970-1955 | Farashin AS1444 | AFNOR | GB |

| 42CrMo4 | 1.7225 | 38hm ku | 4140 | Saukewa: SCM440 | 708M40 | EN19A | 4140 | 42CD4 | 42CrMo |

Karfe 42CrMo4

Aikace-aikace

Wasu wuraren aikace-aikacen yau da kullun don EN 1.4021

Pump- da Valve sassa, Shafting, Spindels, Piston sanduna, Kayan aiki, Stirrers, kusoshi, Kwayoyi

TS EN 1.4021 Zoben ƙirƙira, Ƙarfe Bakin Karfe don Slewing zobe

Girman: φ840 x L4050mm

Ƙirƙirar (Aiki mai zafi) Ƙarfafa , Tsarin Maganin zafi

| Ƙirƙira | 1093-1205 ℃ |

| Annealing | 778-843 ℃ tanderun sanyi |

| Haushi | 399-649 ℃ |

| Daidaitawa | 871-898 ℃ iska sanyi |

| Austenize | 815-843 ℃ ruwa quench |

| Rage damuwa | 552-663 ℃ |

| Quenching | 552-663 ℃ |

DIN 42CrMo4 Alloy Karfe Mechanical Properties

| Girman Ø mm | Bayar da damuwa | Ƙarƙashin Ƙarƙashin Ƙarfafawa, | Tsawaitawa | Hardness HB | Tauri |

| Rp0.2, N/nn2, min. | Rm, N/nn2 | A5,%, min. | KV, Joule, min. | ||

| <40 | 750 | 1000-1200 | 11 | 295-355 | 35 a 20ºC |

| 40-95 | 650 | 900-1100 | 12 | 265-325 | 35 a 20ºC |

| >95 | 550 | 800-950 | 13 | 235-295 | 35 a 20ºC |

| Rm - Ƙarfin ɗaure (MPa) (Q +T) | ≥ 635 |

| Rp0.2 0.2% ƙarfin hujja (MPa) (Q +T) | ≥440 |

| KV - Tasirin makamashi (J) (Q +T) | +20° |

| A - Min. elongation a karaya (%) (Q +T) | ≥20 |

| Z - Ragewa a ɓangaren giciye akan karaya (%)(N+Q +T) | ≥50 |

| Taurin Brinell (HBW): (Q +T) | ≤192HB |

KARIN BAYANI

NEMAN MAGANA A YAU

KO KIRA: 86-21-52859349