Theforging materialskunyanya kabhoni simbi uye alloy simbi, inoteverwa nealuminium, magnesium, mhangura, titanium uye alloys avo.Mamiriro ekutanga echinyorwa ibar, ingot, simbi poda uye simbi yemvura.Chiyero chemuchinjiko-chikamu nharaunda yesimbi isati yasvika uye mushure mekushanduka inonzi iyoforging ratio.Sarudzo chaiyo yeforging ratio, tembiricha yekudziya inonzwisisika uye nguva yekubata, inonzwisisika yekutanga yekubikira tembiricha uye yekupedzisira yekubikira tembiricha, inonzwisisika huwandu hwe deformation uye deformation kumhanya zvine simba guru pakuvandudza kunaka kwechigadzirwa uye kuderedza mutengo.

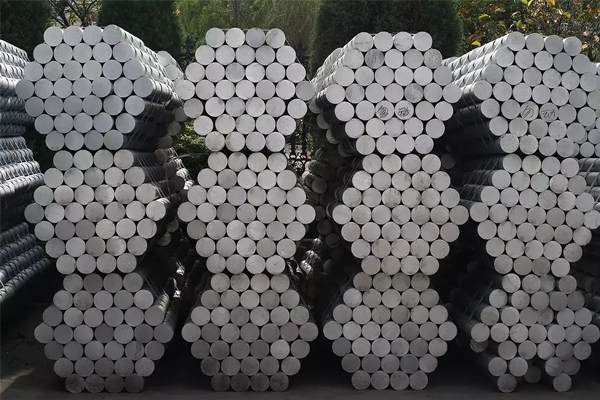

General diki uyezvepakati forgingsakatenderedzwa kana masikweya mbariro semabhiridha.Iwo mabhawa ane yunifomu yezviyo chimiro uye yakanaka michina zvivakwa, chaiyo chimiro uye saizi, yakanaka yemhando yepamusoro, yakanakira kugadzirwa kwemazhinji.Chero bedzi tembiricha yekudziya uye deformation mamiriro akadzorwa zvine musoro, zvakanakaforgingsinogona kugadzirwa pasinakugadzira kukurudeformation.

Ingot inoshandiswa chetemafogi makuru.Iyo ingot ndeye-yakakanda chimiro ine yakakura columnar makristasi uye yakasununguka nzvimbo.Naizvozvo, iyo columnar makristasi anofanirwa kuputswa kuita tsanga dzakatsetseka kuburikidza nehombe yepurasitiki deformation, uye yakasununguka compaction inogona kuwana yakanakisa simbi chimiro uye michina zvinhu.

Powder forging inogona kugadzirwa kubva pre-yakagadzirwa poda metallurgy preforms mushure mekudzvanya nekupfurwa pasi pekupisa.kufa nekugadzirapasina kuputika.Forgingspoda iri pedyo nekuwanda kwezvakajairwakufa forgings, ine yakanaka mechanical properties uye yakakwirira yakarurama, iyo inogona kuderedza kucheka kunotevera.Powder forgings ine yunifomu yemukati chimiro uye hapana kupatsanurwa kunogona kushandiswa kugadzira magiya madiki uye mamwe workpiece.Nekudaro, mutengo wehupfu wakakwira zvakanyanya kupfuura iwowo bhari, saka kushandiswa kwayo mukugadzira kunogumira.,

Chimiro chinodiwa uye zvimiro zvekufa forgingsinogona kuwanikwa nekuisa static kumanikidza kune yemvura simbi inodururira mukamuri yekufa kuti iite kusimba, kupenya, kuyerera, deformation yepurasitiki uye fomu pasi pechiito chekumanikidza.Liquid metal die forging inzira yekugadzira pakati pekufa kukandira uye kufa forging, kunyanya yakakodzera kune dzakaomarara dzakatetepa-madziro zvikamu zvakaoma kuumbwa neakajairwa.kufa nekugadzira.

Forgingzvinhu mukuwedzera kune zvakajairwa zvinhu, senge akasiyana kuumbwa kwekabhoni simbi uye alloy simbi, inoteverwa nealuminium, magnesium, mhangura, titanium uye alloys ayo, yakanyanya kupisa iron base alloy, nickel base superalloy, cobalt-based superalloy deformation yealloy. zvakare INOSHANDISA yekuforoma kana kutenderedza nzira, iyo chete alloy nekuda kwenzvimbo yayo yepurasitiki yakamanikana, saka iyoforgingkuoma kuchava kwakakura, Different zvinhu kudziyisa tembiricha, yakavhurika forging tembiricha uye ekupedzisira forging tembiricha vane zvakasimba zvinodiwa.

Nguva yekutumira: Mar-14-2022